3D printing has had an impact on a range of industries, from aerospace and automotive parts, to culinary and novelty creations. For the most part, however, it is used as a prototyping or experimental tool rather than as a means of speedy, economical mass-market goods production. That may soon change, as sneaker and athletic apparel company Adidas is getting ready to launch a mass-produced, 3D printed sneaker. Could their approach create a new trend in retail goods production?  Image Source: The Verge A Sneaker Design For 3D Printed Mass Production After teaming up with 3D printing manufacturing company, Carbon, Adidas has designed, developed, and is ready to debut the Futurecraft 4D. The shoe is an improved version of the 3D Runners, a limited edition concept sneaker released in 2016—and hindered from the mass-market by it’s high price tag. The new and improved edition may still come with an exclusive cost to match its limited debut quantity of 5,000 pairs, but it’s been specifically modified for mass production. An Accelerated, Bottom Up Process The Futurecraft 4D sneaker is created through an accelerated 3D printing method called Digital Light Synthesis. While conventional 3D printing produces objects by layering powdered or liquid resin materials from the top down, this process builds a product continuously from the bottom up. These sneakers also start with a liquid resin, but, through the use of digital light, the resin can be solidified from a more ideal production point—in this case the tip of the midsole. An ultra-thin layer of air also prevents the resin from sticking to the printing surface as it sets.

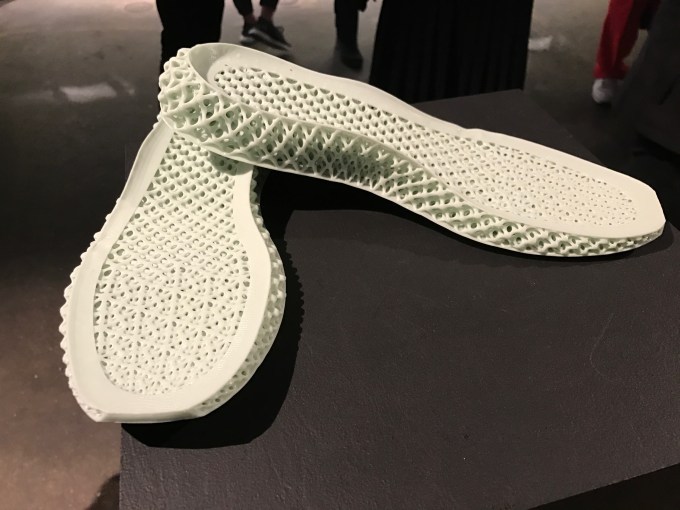

Image Source: The Verge A Sneaker Design For 3D Printed Mass Production After teaming up with 3D printing manufacturing company, Carbon, Adidas has designed, developed, and is ready to debut the Futurecraft 4D. The shoe is an improved version of the 3D Runners, a limited edition concept sneaker released in 2016—and hindered from the mass-market by it’s high price tag. The new and improved edition may still come with an exclusive cost to match its limited debut quantity of 5,000 pairs, but it’s been specifically modified for mass production. An Accelerated, Bottom Up Process The Futurecraft 4D sneaker is created through an accelerated 3D printing method called Digital Light Synthesis. While conventional 3D printing produces objects by layering powdered or liquid resin materials from the top down, this process builds a product continuously from the bottom up. These sneakers also start with a liquid resin, but, through the use of digital light, the resin can be solidified from a more ideal production point—in this case the tip of the midsole. An ultra-thin layer of air also prevents the resin from sticking to the printing surface as it sets.  Image Source: Tech Crunch Faster Production Of Improved Footwear While the fabric portion of the sneaker is manufactured and attached to the sole through ordinary production methods, Carbon’s Digital Light Synthesis allows for much speedier sneaker manufacturing, as well as new design and material possibilities for the Adidas brand. For athletes, the complex geometry incorporated into the 3D sole could be easily modified for a more comfortable, supportive, and responsive shoe. [embed]https://youtu.be/DFtVF2DdSuM[/embed] Scaleable For More Industries Whether the Futurecraft 4D will signify a 3D printed sneaker revolution may not be known until pairs go up for sale this fall. The production potential of this 3D printing method is already generating buzz as a manufacturing means that could be scaled to create all different types of products for all different types of industries in a fast, economic, and reliable way. Could these shoes mark the beginning of 3D printing mass production of even more products? Tell us what you think in the comments. Article Sources http://money.cnn.com https://techcrunch.com http://www.theverge.com https://techcrunch.com

Image Source: Tech Crunch Faster Production Of Improved Footwear While the fabric portion of the sneaker is manufactured and attached to the sole through ordinary production methods, Carbon’s Digital Light Synthesis allows for much speedier sneaker manufacturing, as well as new design and material possibilities for the Adidas brand. For athletes, the complex geometry incorporated into the 3D sole could be easily modified for a more comfortable, supportive, and responsive shoe. [embed]https://youtu.be/DFtVF2DdSuM[/embed] Scaleable For More Industries Whether the Futurecraft 4D will signify a 3D printed sneaker revolution may not be known until pairs go up for sale this fall. The production potential of this 3D printing method is already generating buzz as a manufacturing means that could be scaled to create all different types of products for all different types of industries in a fast, economic, and reliable way. Could these shoes mark the beginning of 3D printing mass production of even more products? Tell us what you think in the comments. Article Sources http://money.cnn.com https://techcrunch.com http://www.theverge.com https://techcrunch.com

The following post Massmarket 3D Printed Shoes Soon to Debut Read more on: http://www.magoda.com

No comments:

Post a Comment